Blue Ox� and Roadmaster� are trademarks of their

respective companies.

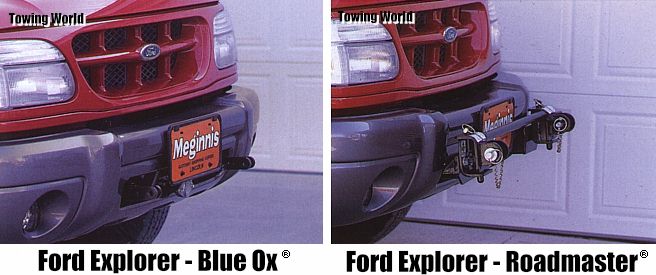

Why Blue Ox baseplates?

Choosing Blue Ox is like having a base plate custom

made for your vehicle. With hidden reinforcements, Blue Ox baseplates

leave little evidence of their existence. They're easy on the

suspension and even easier on the eye. See for yourself what

a difference Blue Ox makes on today's favorite towed vehicles.

More Baseplate

Comparisons (Jeep Grand Cherokee, Saturn, Chevy Malibu)

Why do I need a baseplate?

The baseplate is a crucial first element for any towing system.

The baseplate provides a safe point of attachment to the vehicle,

and ideally will distribute towing pressure to the frame of

the vehicle equally. The baseplate should not interfere with

the integrity of the vehicle's suspension or alignment. Baseplates

bolt to the frame of the vehicle, rather than on the bumper.

Bumpers on many newer vehicles are not strong enough to attach

a baseplate to. Some older four wheel drive vehicles do have

bumpers capable of supporting a baseplate, for example, the

'95 and older Jeep Wrangler.

What styles of baseplates are available?

There are basically two styles of baseplates/brackets on the

market today. First, the multi-piece bracket which consists

of two single arms and a cross angle which the tow bar attaches

to. This type of bracket can cause undue pressure to the vehicle.

For example, one independent arm may be applying pressure forward,

while the other arm may apply backward pressure or even sideways.

The independent arms may also shift due to bumps or impacts

incurred during normal driving. This may result in difficulty

hooking up the tow bar. Also, multi-piece brackets generally

reduce ground clearance. These types of brackets are widely

used, but we feel that the Blue Ox one-piece welded design is

superior for several reasons. Below is a picture of the Blue

Ox BX2218 for the Honda CR-V baseplate. As you can see, this

baseplate is one solid piece and will easily bolt to the frame

of the vehicle without having to assemble any odds and ends

beforehand.

�

What process does the manufacturer take to build a baseplate?

(Information gathered with the cooperation of Blue Ox) The

manufacturer must first bring the vehicle that is being "fit"

in to the factory. In some cases, the manufacturer will get

permission from a local car dealership to use a car off of the

lot for the fit process. In most cases, though, customer's vehicles

are used. For example, the Blue Ox engineers use customer's

vehicles in 90% of their new fits. Next, they check the previous

year's baseplate against the new car to find out if the old

model baseplate will carry over. If it doesn't fit, they then

remove the bumper and check the frame and the metal bumper for

existing holes that can be used to fasten the baseplate to the

frame. Ideally, they design the baseplate so that it comes through

the grill of the car. This exclusive Blue Ox design is very

appealing to the eye and is less noticeable when the vehicle

is not being towed. In some cases the baseplate will protrude

out from the air dam area rather than the grill. Once they can

identify where the ideal place is to bolt the baseplate to,

they build a prototype baseplate on to the car. They build the

baseplate so that it fits beneath the metal bumper and in some

cases utilizes the vehicle's tie down brackets. Blue Ox also

designs baseplates so that it won't "bottom out" during

regular driving conditions. In fact, Blue Ox states that in

all cases, the vehicle itself will bottom out before the baseplate

will. Once the prototype is built, Blue Ox produces a duplicate.

With the duplicate, they perform various tests.

- Distance Test

- Swerving Test

- Test how the vehicle pulls out of a turn

- Test how the vehicle pulls from a complete stop

- Dip test through a 2" dip

- Circle test to see how the baseplate performs with pressure

on both sides

They then weigh the baseplate to find out what Class of tow

bar it needs. The entire fit process takes approximately 5 days

per vehicle.

What does installation of a baseplate involve?

Most baseplates bolt to existing holes in the vehicle's frame.

On occasion, you may have to drill a new hole, notch the grill

or belly pan, or cut the fascia of the vehicle. Some baseplates

involve removing the bumper and headlights of the vehicle during

installation. The model notes in the manufacturers 'fit list'

can be helpful in determining the difficulty of the installation.

Call us at 1/800-566-9869 to find out what is involved in the

installation for your vehicle.

Who is qualified to install a baseplate?

Most manufacturers recommend that baseplates be installed by

an experienced or certified Hitch Installer. It's a good idea

to read the Installation Instructions thoroughly before beginning

any installation, if you plan to install the baseplate yourself.

Also, be sure you have all the necessary tools and hardware

before beginning the installation. In many cases, a baseplate

installation will require two people for certain steps, so have

a helper nearby if possible.

How do I find out if there is a baseplate for my vehicle?

Check out our baseplate application

table to find out if there is a Blue Ox baseplate for your

vehicle.

�

![]()

![]()

![]()

![]()